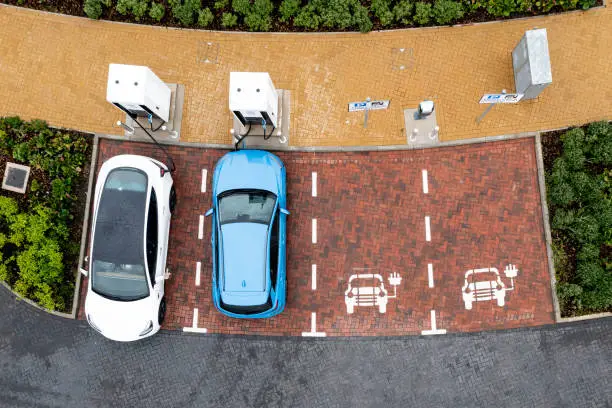

Rising EV adoption around the globe has dramatically accelerated the need for shadow-free, dependable high-speed charging networks. For B2B enterprises preparing to roll out EV infrastructure, naming the best EV charging manufacturer is pivotal to securing superior, scalable performance that delivers payback over the life of the asset. This article drills into the benchmarks that matter when evaluating the industry’s foremost suppliers and elucidates the performance traits that separate market leaders from the pack.

Understanding the Role of EV Charger Manufacturers

EV charger manufacturers are the unseen enablers of the entire electrification supply chain. They engineer and fabricate the hardware and interoperability-layer software that drive charging stations—offering everything from ultra-rapid, DC units to intelligently staggering, networked wall boxes. Performance attributes differ from vendor to vendor, accentuating that pure price metrics can mislead. Decision makers should stress-tested reliability, first-class service, and progressive technology rollouts.

A reliable EV charging manufacturer shapes processes from streamlined commissioning to lowered maintenance outlays. Tier-one suppliers typically bundle hardware with advanced services: real-time load-balancing packages, cloud observability services, and frictionless mobile user clients. Those integrated extras can dramatically reduce the complexity and TCO of running multi-site fleets, tipping the ROI scales long before warranties expire.

Key Performance Metrics to Consider

Performance metrics should drive any comparison between EV charger manufacturers. Businesses can zero in on the following:

- Charging speed: Opt for fast and ultra-fast chargers that shrink vehicle dwell time and enhance the driver experience. Look for models that achieve high output while maintaining proven safety margins—this is a hallmark of market leaders.

- Energy efficiency: Chargers that waste very little energy pay for themselves over the operational life of the asset. Seek manufacturers willing to share comprehensive efficiency graphs so energy savings can be accurately projected.

- Durability and reliability: Deployments occur in parking garages, remote construction sites, and cold-storage docks, so chargers must endure extreme heat, moisture, and wear. Hardware that is tested to the full range of conditions is non-negotiable.

- Smart capabilities: Built-in connectivity, remote diagnostics, over-the-air software pushes, and load balancing drive down operating headaches. Firms that develop software and hardware as a single system rather than retrofit connectivity later usually offer the smoothest performance.

- Compliance and certifications: Chargers that meet recognized safety and quality frameworks in all target jurisdictions help firms avoid regulatory hiccups and delays. Documented certifications should accompany pricing, not be supplied on request.

Assessing manufacturers against these beacons of performance enables B2B decision-makers to identify the partners that deliver lasting ROI rather than the lowest upfront price.

The Importance of Scalability and Support

In commercial and industrial deployments, scalability looms large on decision-makers’ radar. Most organizations pilot with a handful of chargers, then expand in orderly increments as usage rises. The leading suppliers of commercial charging solutions have responded with tightly modular architectures, so increases in charging ports require only the addition of pre-tested racks and software licenses, never wholesale rewiring. Buyers can therefore scale up in steps and stretch the lifetime of their capital budgets without worrying that their initial, modest installations will one day become a dead end.

Complementary to scalable architecture is dependable, multi-tier support. Manufacturers that bundle long-term warranties, rapid-response helpdesks, and, where appropriate, mobile service crews eliminate costly downtime and avoid the drain of piecemeal repairs. In a large rollout, such coverage can outweigh a lower price on the charger in the base quote. Service availability in the regional market becomes a proxy for risk assessment, with organizations prioritizing suppliers whose technicians are minutes, not flights, away.

read more : Navigating Cannabis Dispensaries: A Beginner’s Guide

Comparing Charging Technologies

Manufacturers usually propose a suite of charging architectures, the most common being AC Level 2 and DC fast charging. Each technology optimally serves a different context.

- AC Level 2 chargers power up in settings where vehicles dwell for extended periods, such as office parking garages, multifamily residences, and mixed-use commercial complexes. The typical 19 to 40 kilowatt output delivers range sufficient for overnight or day-shift commuters.

- DC fast chargers are engineered for rapid replenishment in scenarios with high vehicle turnover, such as public transit terminals and commercial fleet depots. Systems apply advanced sensing and predictive software to govern output, curbs thermal growth, and optimize power procurement and load shedding, resulting in reliable, highly efficient service.

Organizations must map out operational needs, pinpoint the technological solutions that fit, and partner with manufacturers who can deliver a full spectrum of compatible charging options. Whenever feasible, opting for a single vendor that encompasses multiple technologies can streamline integration efforts and lower ongoing maintenance burdens.

Evaluating Industry Reputation and Innovation

Performance extends beyond technical specifications; the combination of ongoing innovation and credible market standing is equally decisive. Outstanding EV charger vendors consistently channel capital into R&D focused on raising charging velocity, optimizing energy consumption, and enhancing the driver interface. Those that deploy advanced solutions, for instance, AI-driven energy optimization and forward-looking maintenance analytics, typically offer stronger performance longevity.

Procurement teams on the B2B side should supplement technical briefs with independent endorsements, award recognitions, and detailed case studies of similar deployments. Reliable manufacturers publish performance targets and provide complete, measurable records on system uptime, reliability, and operational efficiency. A sound market reputation is frequently a lagging indicator of lower maintenance incidents and more synergistic long-term alliances.

Conclusion

Selecting the appropriate EV charging manufacturer is a tactical move for any enterprise expanding EV infrastructure. By scrutinizing performance indicators, scalability road maps, technological options, and credible industry standings, procurement teams position their charging networks for sustained efficiency and reliability.

For firms planning to roll out commercial EV charging, picking a charger supplier isn’t just about the price tag today; it’s about backing a technology partner that will keep the asset relevant for the long haul. Teams that choose makers known for durability, forward-thinking software, and ongoing customer care will see smoother charger performance, slashed repair bills, and a head start over rivals entering the electric-vehicle arena after them.

Suppliers which lead in equipment design, built-in intelligence, and comprehensive long-term support will typically produce the highest-return installations. Giving these dimensions the highest weight ensures that any charging network will remain strong, adaptable, and ready to turn a profit.