In the fast-moving world of factories and assembly lines, knowing exactly where a machine part is can make all the difference. That’s where absolute value sensors come into play. Think of them as the ever-reliable GPS in a car; no matter how many times you switch the engine off and on, they always know exactly where you are. Unlike their incremental cousins—who need a fresh starting line drawn every time you power up—absolute sensors fire up and deliver position data right away. That quick response can keep a plant running smoothly, safely, and on schedule.

Companies that build equipment for manufacturing, robotics, packaging, and even energy production rely heavily on this kind of straightforward accuracy. If you design, sell, or maintain those machines, it helps to know how absolute sensors work, why they shine, and how they can be dropped into existing systems without a ton of extra rewiring. This article will walk you through the basic mechanics, real-world uses, and the latest upgrades in absolute encoding technology.

What Exactly Is an Absolute Value Sensor?

At its core, an absolute value sensor—most people just call it an absolute encoder—tracks the position and angle of a rotating shaft and sends back a one-of-a-kind digital code for every spot it can land on. Because it saves that information in non-volatile memory, the code doesn’t vanish when the lights go out. When you power the system up again, there’s no waiting around for a calibration routine or a tedious homing cycle; the controller instantly knows where the axis is sitting.

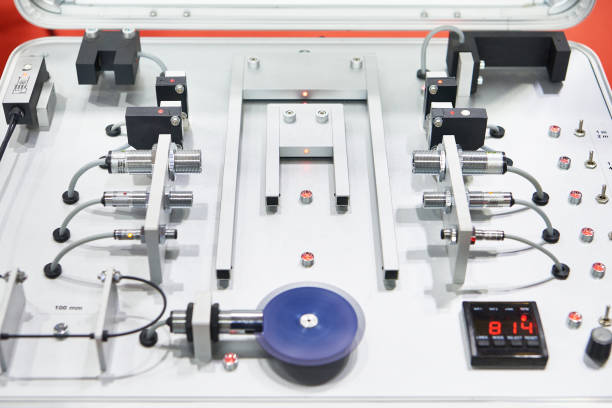

Absolute value sensors rely on optical, magnetic, or capacitive technologies to read special patterns that are engraved on a rotating disk or a long strip. Once the sensor passes over the pattern, it translates that information into binary signals that precisely tell the control system where the shaft or moving part is located. Depending on the job at hand, manufacturers can choose between two basic types of sensors:

- Single-turn sensors measure the angle of a shaft for the duration of one complete turn.

- Multi-turn sensors keep track of position over countless revolutions by using tiny internal batteries, counters, and miniature gear trains.

Because of their fail-safe design, absolute sensors are often found in applications where downtime is costly and quick system recovery is a must.

What They Bring to B2B Industrial Operations

Absolute value sensors fit perfectly in factories and plants where keeping machines running smoothly is a top priority. For original equipment makers, system integrators, and anyone else that assembles complex machines, these devices provide a host of advantages:

- Instant Position Feedback: The sensor reports its location the moment power is applied, so engineers can avoid long startup waits and potential mechanical damage.

- High Resolution: Fine measurement granularity means better control, which translates into tighter tolerances and improved product quality on automated production lines.

- Built to Last: With protection ratings of IP67 or better, many sensors shrug off dust, oil, moisture, and vibrations without missing a beat.

- Flexible Outputs: Support for popular communication standards such as SSI, BiSS, CANopen, and EtherCAT means they will fit right in with existing PLCs and control systems with minimal fuss.

- Less Downtime: Because absolute sensors know exactly where they are at all times, machines don’t have to waste time resetting or re-homing after a power cut or emergency stop.

Their rugged design and built-in intelligence fit perfectly with the goals of Industry 4.0, where real-time data and direct machine-to-machine chat are now the norm.

Where You’ll Find Absolute Sensors

Absolute sensors are popping up in all kinds of industries that can’t afford a slip in accuracy:

- Robotics: Think of robotic arms in factories or automated guided vehicles (AGVs) on warehouse floors. These sensors keep orientation locked in so every move lands just right.

- Packaging Lines: On fast-moving packaging machines, precise alignment is key. Absolute sensors time each layer or box with pinpoint timing to avoid jams.

- Renewable Energy: Wind turbine blades and solar panel arrays turn or tilt for maximum sunlight or wind. Absolute encoders tell them exactly where to point at any moment.

- Elevators and Lifts: No one enjoys a jerky ride. Absolute sensors ensure that elevators glide smoothly to each floor, stopping right on the mark.

- Medical Gear: In surgery rooms or labs, machines like robotic scalpel arms and MRI beds depend on exact position feedback to prevent costly mistakes and protect patients.

By serving up real-time, fixed-location data, these sensors help automated systems run faster, last longer, and keep costly breakdowns at bay.

Key Factors for Choosing Absolute Value Sensors

When a B2B manufacturer looks to install absolute value sensors, a few practical questions guide the decision-making process:

- Mounting Style: Whether the shaft is hollow or solid, the sensor must fit the existing hardware without modification that adds time or extra cost.

- Resolution Needs: Some tasks need very fine detail, while others can work with less. More bits give sharper measurements, but they can drive up both the sticker price and the workload on downstream systems.

- Interface Compatibility: An easy setup usually starts with making sure the output format—whether analog voltage, current, or digital code—matches the control platform already in use.

- Environmental Protection: A high IP rating and an allowable range for temperature and humidity let engineers confirm that the sensor will survive factory floors, outdoor locations, or any other demanding setting.

- Signal Redundancy: Safety-first designs often specify dual-channel or redundant encoders so that a backup kicks in if the primary channel fails.

For firms refreshing or expanding their automation lines, reliable sensors and supporting hardware form the backbone of success. To discover SSR relays and other complementary components that streamline sensor integration, check out this https://www.omchsmps.com/de/produkt-kategorie/ssr-relay/ where you’ll find options built for tough industrial power chores.

How OMCH Supports Sensor and Automation Projects

OMCH has earned the trust of manufacturers by consistently delivering quality automation parts, from sensors and relays to power supplies and controllers. Drawing on years of hands-on sensor work, OMCH produces both off-the-shelf items and tailored solutions that meet the wide-ranging demands of modern industry.

OMCH’s product lineup goes beyond just inductive and photoelectric sensors. It also features high-resolution absolute value sensors that are compact, tough, and built to last. The company keeps a close eye on quality at every stage and backs its international customers with custom automation solutions that come straight from its own research, engineering, and manufacturing teams.

As factories get smarter and more connected, OMCH keeps pace with the growing demand for accuracy, compatibility, and lasting performance. Its modular designs allow B2B partners to plug in new equipment and expand their automation systems, so they can scale up without second-guessing the fit or reliability of the technology.